Plastic components that appear simple on the surface often hide complex engineering problems beneath. Poor dimensional accuracy, short shots, excessive warpage, and frequent mold repairs usually trace back to weaknesses in injection mold design engineering rather than machine capability or material choice. When these issues reach production, the impact is expensive: rejected parts, extended cycle times, delayed deliveries, and strained relationships between suppliers and customers. The situation becomes more critical when molds are expected to run for high volumes or tight tolerances, where even minor design oversights can multiply into serious operational losses.

These problems often escalate because mold design decisions are made too late or without sufficient integration between product design, material behavior, and manufacturing constraints. Cooling channels placed without thermal balance consideration, gate locations selected only for convenience, or inadequate draft angles can lock inefficiencies into the mold for its entire service life. Correcting such flaws after steel cutting is rarely economical.

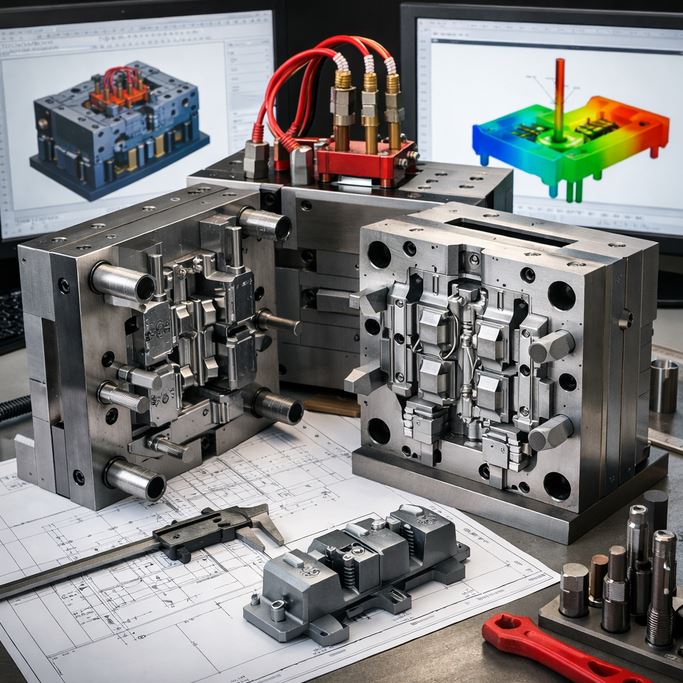

Injection mold design engineering addresses these risks by translating product intent into a manufacturable, durable, and controllable mold system. Through structured analysis, simulation, and experienced engineering judgment, design decisions are validated early, ensuring predictable quality, stable production, and long-term cost control.

What Is Injection Mold Design Engineering?

Injection mold design engineering is the disciplined process of developing mold structures, components, and systems that enable consistent plastic part production under defined operating conditions. It bridges product design, material science, and manufacturing reality, ensuring the mold performs reliably throughout its lifecycle.

This engineering activity goes beyond drafting mold layouts. It involves evaluating part geometry, resin flow characteristics, thermal behavior, ejection mechanics, and machine compatibility. Each design choice is assessed for its effect on part quality, cycle time, maintenance requirements, and tooling longevity. A properly engineered mold reduces variability, supports repeatable production, and protects capital investment in tooling.

Core Principles of Injection Mold Design Engineering

Effective mold design engineering rests on several technical principles that must be addressed together rather than in isolation. Ignoring one aspect often compromises the entire system.

Part Analysis and Design for Manufacturability (DFM)

Part geometry defines the foundation of the mold. Wall thickness uniformity, rib proportions, boss design, and draft angles all influence resin flow and cooling behavior. Design for Manufacturability reviews identify features that may cause sink marks, air traps, or difficult ejection. Early DFM feedback allows design adjustments before tooling costs are committed, aligning product requirements with molding realities.

Material Selection and Behavior

Different polymers respond uniquely to heat, pressure, and shear. Shrinkage rates, viscosity profiles, and fiber orientation must be understood and accounted for in mold cavity sizing and gate placement. Injection mold design engineering ensures that material behavior is not assumed but engineered into the mold geometry and processing window.

Gate, Runner, and Venting Design

The delivery of molten resin into the cavity determines fill balance and surface quality. Gate type and location affect weld lines, cosmetic appearance, and structural strength. Runner systems must balance pressure loss while maintaining thermal stability. Proper venting prevents gas entrapment, reducing burn marks and incomplete fills. These elements work together to control flow predictability.

Cooling System Design: The Key to Cycle Time Control

Cooling often represents the longest portion of the molding cycle, making it a primary lever for productivity improvement. Injection mold design engineering focuses on creating uniform heat extraction across the cavity and core surfaces.

Cooling channel layout, diameter, and proximity to molded surfaces must be optimized to avoid thermal gradients. Uneven cooling leads to warpage, residual stress, and dimensional instability. Advanced designs may include conformal cooling or baffle systems where conventional drilling cannot achieve uniform temperature distribution. Proper cooling engineering shortens cycle time while preserving part quality and mold durability.

Ejection System Engineering and Mold Reliability

Ejection systems must remove parts consistently without deformation or surface damage. Pin placement, ejector stroke, and synchronization with mold opening are critical considerations. Injection mold design engineering evaluates part geometry and material stiffness to determine appropriate ejection strategies.

Poorly engineered ejection leads to sticking, part damage, or excessive wear on mold components. By analyzing demolding forces and contact areas, engineers can design systems that release parts efficiently while minimizing maintenance and downtime.

Validation, Inspection, and Process Control Integration

A mold design is only successful if it produces parts that meet dimensional and functional requirements. This is where inspection and validation planning become essential. During mold development, engineers consider how parts will be measured and verified in production.

Integrating dimensional control strategies, such as using a dedicated checking fixture, ensures that molded parts can be inspected consistently and efficiently. This alignment between mold design and quality control reduces ambiguity during production ramp-up and supports faster issue resolution when deviations occur.

Common Challenges Addressed by Injection Mold Design Engineering

Injection mold design engineering proactively mitigates risks that frequently appear in poorly planned tooling projects.

- Warpage and dimensional instability caused by uneven cooling or improper material flow paths.

- Short shots and burn marks resulting from inadequate venting or restrictive gate design.

- Excessive cycle times linked to inefficient cooling layouts.

- High maintenance costs due to poor component accessibility or unbalanced wear patterns.

By addressing these issues at the design stage, engineers protect production efficiency and tooling investment.

The Value of Engineering Expertise in Mold Design

While software tools and simulations are valuable, they cannot replace engineering judgment. Injection mold design engineering relies on experience to interpret analysis results and anticipate real-world behavior inside the mold. Decisions such as balancing cost versus performance, selecting appropriate mold steel, or designing for future production scalability require a practical engineering mindset.

An experienced mold design engineer communicates clearly with product designers, machine operators, and quality teams. This coordination ensures that the mold functions not only on paper but also on the factory floor.

Why Choose PT. Desain Teknik Indonesia for Mold Design Services

PT. Desain Teknik Indonesia provides professional injection mold design engineering services tailored to industrial production requirements. The company combines technical analysis, practical manufacturing insight, and structured documentation to deliver mold designs that are reliable and production-ready.

Services include DFM analysis, complete mold layout design, cooling and ejection system engineering, and coordination with inspection and quality control planning. Projects are handled with a focus on long-term mold performance, not just initial tooling delivery.

If your organization requires dependable injection mold design engineering for new or existing products, PT. Desain Teknik Indonesia is ready to support your project. The team accepts and delivers mold design services aligned with production efficiency, quality consistency, and tooling durability. Contact PT. Desain Teknik Indonesia to discuss your mold design requirements and engineering objectives.